3D Printing is done with our FDM printers

After the design is cleaned up, it is time to make prototypes. For this stage of development, we use FDM (Fused Deposition Modelling). All plastic materials come in on a spool. The material is extruded onto a heated bed, one layer at a time. Materials come in a huge assortment of colours. Many materials are available to build with. Each material has characteristics that make it preferred for their end use. These include PLA, PETG, ABS, Nylon, ASA/PETT, Flexible, Polycarbonate and Carbon Fibre. Some PLA resins have metal or other material infused in them. These can include bronze, marble, and wood.

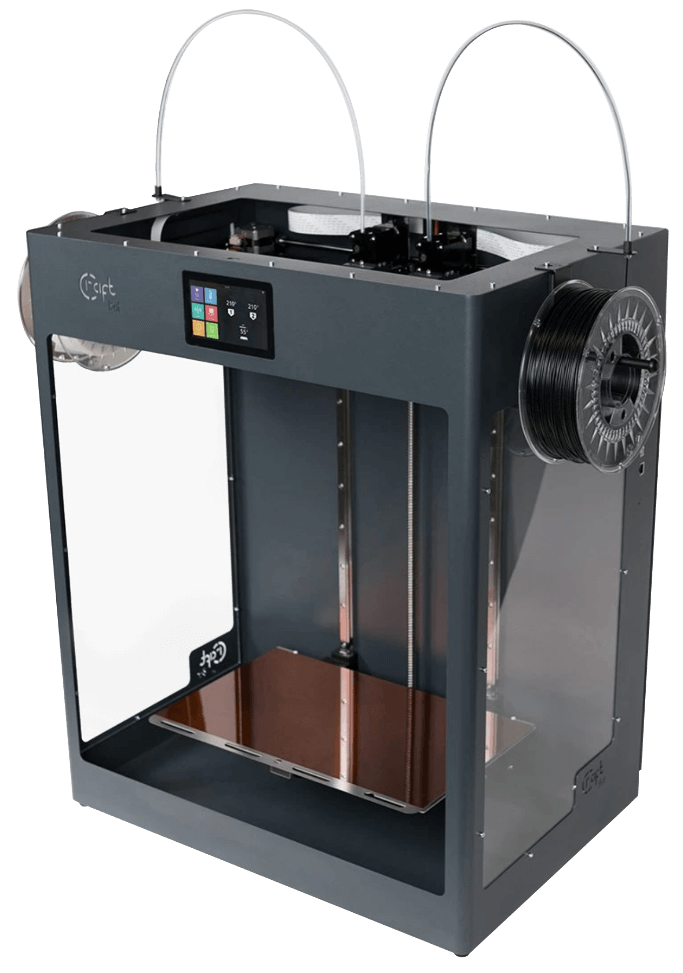

Craftbot Flow Generation IDEX

The IDEX printers have a build volume of 16.7 x 9.8 x 9.8 IDEX XL has a build a volume of 16.7 x 9.8 x 19.5. Both Printers can print dual colour. Another feature of the IDEX machines is their ability to print parts side by side. These parts can be duplicates or mirrored. When in duplication mode the printer is limited to one colour / part.