After data is acquired with the scanners, design begins. The first step in the process is to bring the raw scan data into Geomagic Essentials. In this software we can clean up the scan data. Typical operations include using Mesh doctor to remove bad data. Next operation is to fill holes. Last cleanup operation is decimation. From there the data can be converted into NURBS surfaces. These surfaces are then exported in specific formats compatible with our design software.

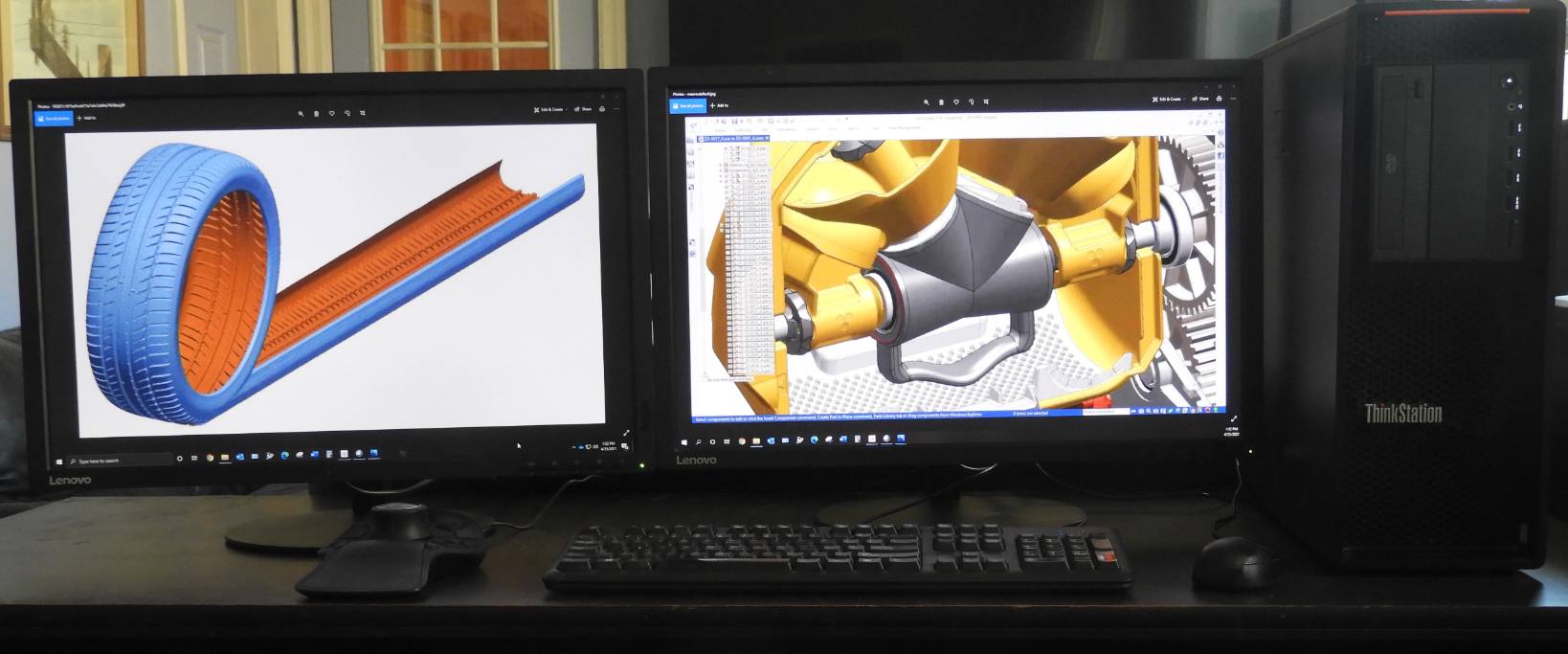

Siemens NX 2306 is the software we use for designing. From this software, the raw NURBS surfaces can be simplified into primitives such as planes, circles, cylinders, cones. Sections can be cut from the surfaces or from the clean scan data with this software. The sections are used to build using Extrude and Boolean operations. Occasionally organic freeform surfaces can be used in a “hybrid” model. This would be the case if scanning wood, rocks, or anything that is not smooth and continuous.